British designer Mark Gabbertas is the Design Guild Mark’s most prolific holder with 20 pieces awarded the designation of design excellence since 2008.

Yorkshire born Mark graduated from Durham University with a degree in Political Philosophy. After eight years as an account manager at the advertising agency, Saatchi and Saatchi, Mark was ready for a change. In 1990 he left advertising to follow his passion and trained as a cabinet maker.

After only two years training, Mark set up on his own company and was commissioned to design the furniture for the Atelier restaurant in Soho, which won the FX Furniture in Practice award in 1995.

In 2002 Mark established the Gabbertas Studio in West London. Gabbertas’s philosophy is to create character through simplicity, giving a lasting design aesthetic. This approach has earned him numerous awards, most recently in 2019 with the William Chair for Gloster and the Oran sofa system for Allermuir both being recognised in our Furniture category.

We caught up with Mark to find out more about Oran.

What initially inspired you to design Oran?

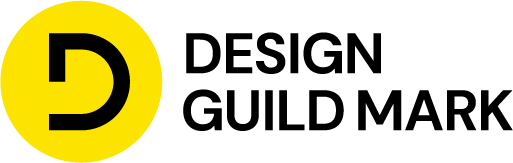

We set out to design a new typology of sofa system. One that had the comfort and some of the aesthetics of a domestic design, but the function of one dedicated to contract use. The Oran system is an extraordinarily flexible modular sofa system that doesn’t look like a modular sofa system. It provides superb levels of comfort that are not normally associated with ‘contract’ style soft seating and allows for different ways of sitting, from the more formal, shorter sit to the more relaxed lounging. It manages to combine therefore the flexibility, durability and function required of a system designed for hospitality and office environments, but with the feel and humanity of a domestic sofa system.

Explain its concept.

The emotion of the design is key to understanding the thinking behind it. The system is rooted in the desire to create a seating program that was suitable for both office and commercial and this balance is critical to the concept. This was realised by a deliberate juxtaposition in the design of the upholstery of the structured and the unstructured, the rigorous and the gentle, the defined and the ambiguous. The rounded and voluminous profile of the upholstery is restrained by a defined seam which leads the eye around the profile of the sofa. Loose cushions incorporate a variation on this seam detail and can be placed as wished to personalise the ergonomics.

How long did the design process take?

Let’s just say it took a long time. On the one hand we were continuously adjusting the proportions and detailing of the upholstery to get this right and at the same time, designing and refining the engineering of the internal construction and frame.

In what way do you think this design is different from anything else available on the market?

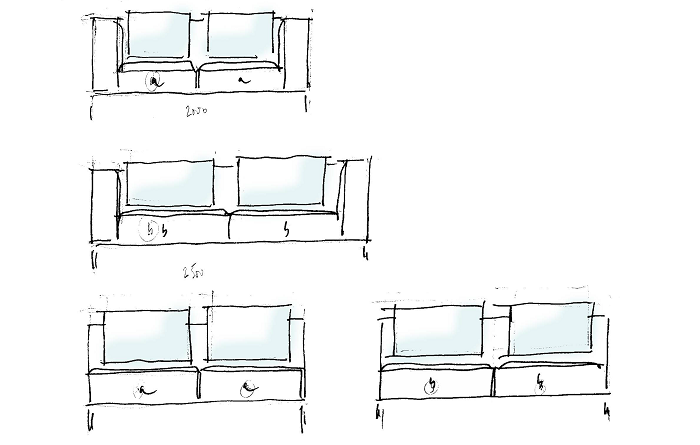

Oran is designed to allow the creation of an infinite number of configurations from a limited number of individual units. There is just a single seat depth, but two seat widths, approximately 750mm and 900mm. The seat widths are available as individual units or are combined in a selected number of double/binary units, along with the option of an integrated table in various sizes.

Critically, the ability to create double units on a single frame minimises the potential clustering of leg elements when creating sofa configurations. There are two key advantages to this approach. From a manufacturing perspective, the system maximises the potential number of units and configurations from the least number of seat and frame sizes possible. From the user’s perspective, it is almost impossible to imagine a configuration that is not achievable with the range of unit sizes and types available.

What was the most challenging aspect of the design?

Well there were two key challenges. First was to achieve sufficient strength in the frame. The design and engineering of the frame was critical to combine two conflicting objectives – to achieve a minimal visible edge profile but enough strength to allow units up to 2000mm in width to work without additional support.

Secondly, we needed all the time to be acutely aware of the need to adhere to the geometric principles of designing a modular system. The geometry of all the seat and table elements is designed to maximise the efficiency of manufacture and flexibility of configuration. Key to this is the interchangeability of different components within the frame skeleton. For example, the upholstered arm and back elements are the same dimension and in turn are both the same as potential table elements, which means that in essence, these become interchangeable at the manufacturing stage within a frame. This in turn means the modularity of the system is maximised as these elements all fit next to each other naturally, which is critical to an efficient modular system.

For more information about Mark, go to gabbertas.com.